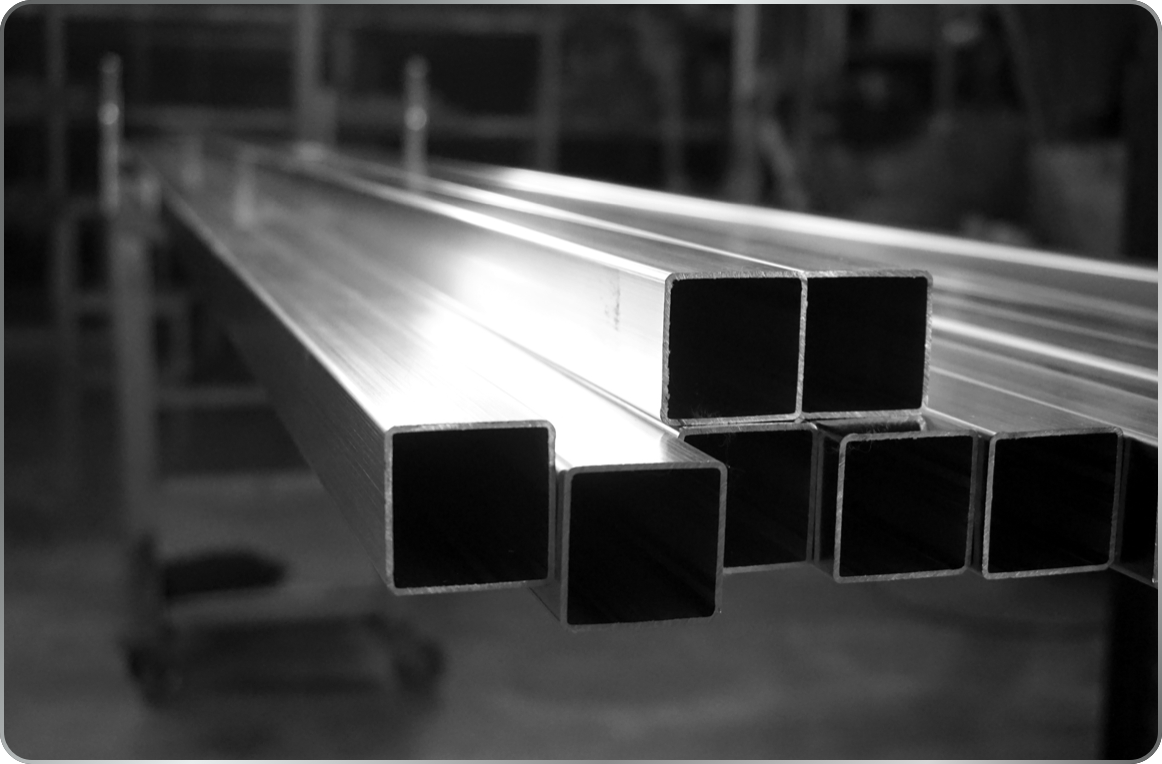

SQUARE TUBING

Square Tubing Overview

Consolidated Metals Inc. delivers high-quality square steel tubing, manufactured to precise specifications and available in a broad range of sizes and gauges to suit your specific requirements. Our flexible stocking programs and ability to customize orders ensure that you get the right product—just when you need it.

Whether you're fabricating trailers, constructing metal buildings, or manufacturing agricultural equipment, CMI's square tubing provides the structural integrity and consistency your operations demand.

Product Specifications

| Size (inches) | 22GA | 20GA | 18GA | 16GA | 15GA | 14GA | 13GA | 12GA | 11GA | 10GA | 9GA | 8GA | 7GA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.75 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.812* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 0.813 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.85 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.875* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 0.984 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 1.000* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 1.125 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 1.187 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 1.2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 1.25 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 1.375* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 1.500* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 1.750* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 1.875* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 2.000* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 2.250* | ● | ● | ● | ● | ○ | ○ | ● | ● | ● | ● | ● | ● | ● |

| 2.362 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 2.5 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 3 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 4 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Legend:

● = Available

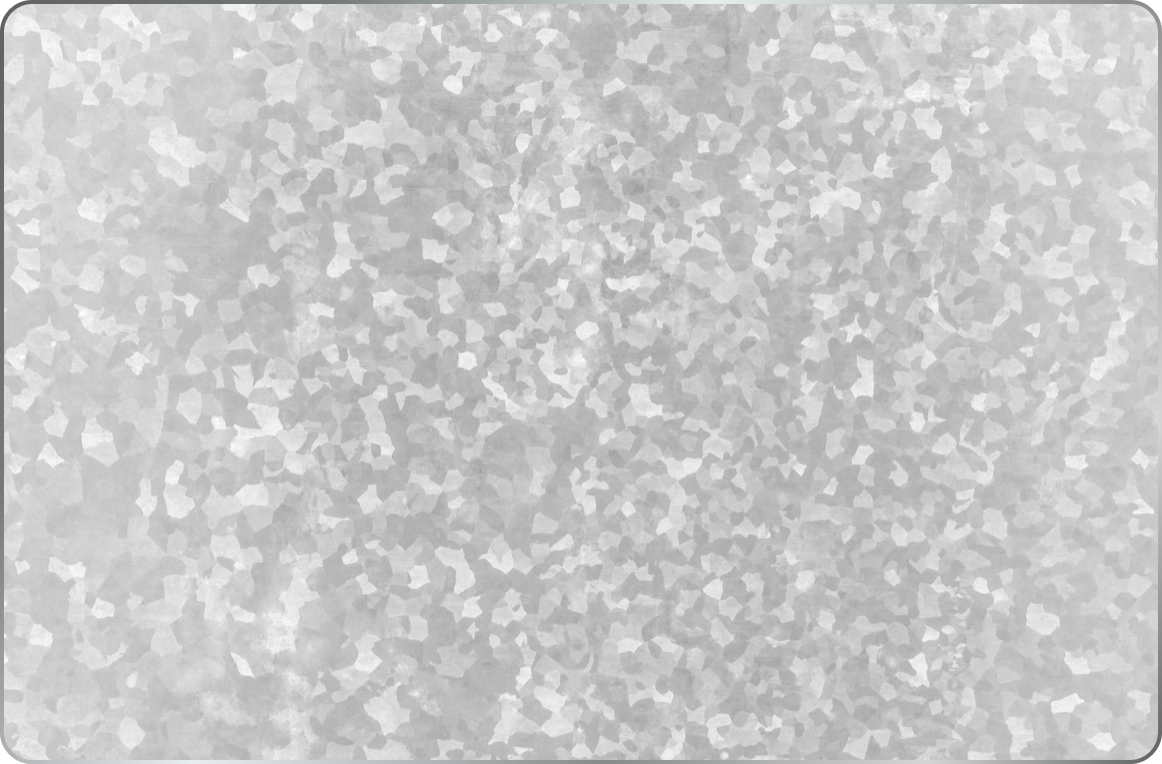

○ = Available with galvanized re-metallization and acrylic clear coating

*Denotes sizes with enhanced coating options

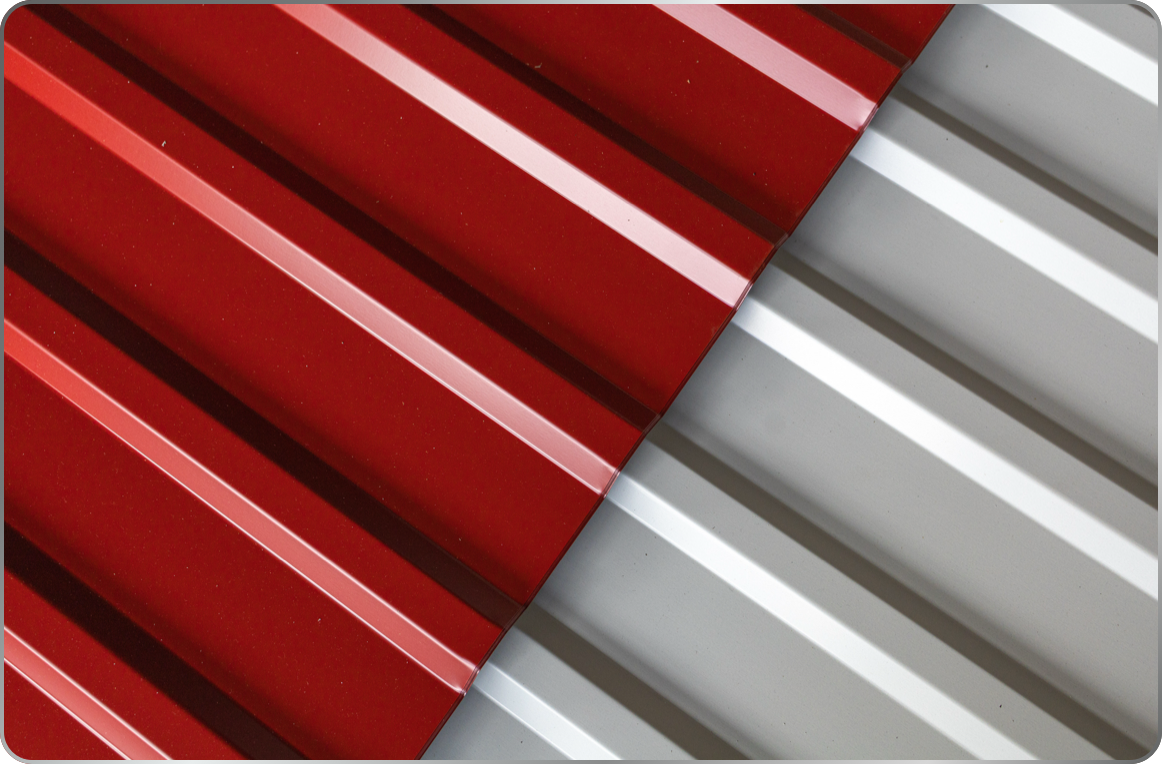

Material & Finish Options

Standard Bare Steel

Raw steel for fabrication and welding applications

Galvanized

Hot-dipped galvanized for superior corrosion resistance

Acrylic-Coated Galvanized

Re-metallized and clear-coated for long-term outdoor durability

Custom Finishes

Paint-ready or powder-coat-prep available upon request

Industries We Serve

CMI square tubing is trusted by manufacturers and fabricators across multiple industries:

- Metal Structures & Construction – Steel buildings, carports, point-of-purchase displays

- Trailers & Transportation – Drop-deck trailers, chassis components

- Scaffolding & Racking – Industrial and commercial support structures

- Agricultural Equipment – Farm gates, fencing systems, continuous bins

- General Fabrication – Custom projects requiring precision-cut square profiles

Value-Added Capabilities

Precision Cutting

- Cut-to-length services from 8" to 79"

- Deburring for smooth, safe edges ready for assembly

Secondary Processing

- Notching – End notching for welded joints and assemblies

- Punching & Drilling – Custom hole patterns, slots, and end-smashing

- Bending – CNC and manual tube bending for complex geometries

Welding & Fabrication

- Five dedicated weld stations with MIG and TIG capabilities

- Robotic welding for high-volume, repeatable production runs

Why Choose CMI Square Tubing?

Flexible Stocking Programs

Flexible Stocking Programs

Secure your supply without overcommitting to bulk orders

Custom Processing

Custom Processing

One supplier for tubing AND fabrication services

100% On-Time Delivery Commitment

100% On-Time Delivery Commitment

Keep your production line moving

Direct Communication

Direct Communication

Dedicated account support, not an automated system

Competitive & Transparent Pricing

Competitive & Transparent Pricing

No hidden fees or surprise upcharges

Build to Suit: Your Vision, Our Precision

At CMI, we understand that standard products don't always fit unique applications. Whether you need custom holes, end-forming, specialty coatings, or integrated fabrication services, our engineering team collaborates with you from design to delivery.

Our build-to-suit approach includes:

- Engineering support and prototype development

- Custom tooling and fixtures for volume orders

- Just-in-time inventory programs to match your production schedules

- Flexible order quantities—no job too small or too large

Ready to Get Started?

Request a Quote

Need pricing on a specific size or custom order? Our team responds within 24 hours with transparent, competitive quotes.

Download Specifications Sheet

Get detailed technical specs, weight charts, and ordering information.

Speak with a Specialist

Have questions about custom processing or stocking programs? Let's talk. Call 904-274-4957 or contact us.